What Is MTM Pipeline Inspection and How Does It Detect Hidden Corrosion?

Pipeline inspection has become a critical engineering practice as modern infrastructure faces increasing operational pressure, aging assets, and higher safety expectations. Understanding what is MTM pipeline inspection is essential for professionals responsible for evaluating the technical condition of buried and operating pipelines without disrupting daily work or introducing additional danger to facilities.

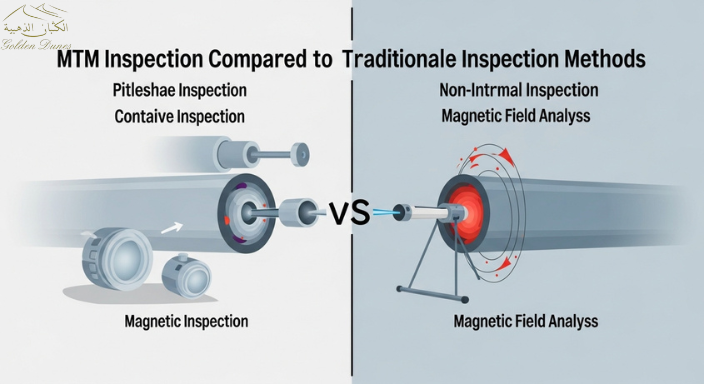

Traditional inspection methods often rely on direct contact with the pipe or require shutdowns that lead to time loss, resource waste, and increased operational risk. In complex industrial environments, especially where oil and gas pipelines extend over large areas, these limitations reduce reliability and delay defect detection related to corrosion, crack formation, and stress concentration within the metal structure.

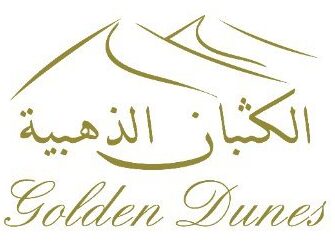

MTM inspection technology introduces a non-contact and non-destructive testing approach based on analyzing changes in the magnetic field surrounding the pipe. By capturing data related to magnetic response, metal loss, and stress conditions, this method enables engineers to detect defects in the metal, assess pipeline condition, and support informed inspection decisions without physical contact or invasive preparation.

Within modern inspection systems, magnetic tomography has evolved as a reliable inspection method capable of operating across different pipeline lengths and environments. Its integration within broader inspection strategies aligns with advanced infrastructure management practices and complements other inspection technologies used across the industry.

For organizations applying advanced inspection technologies as part of their broader engineering framework, insights into MTM inspection are often evaluated alongside other infrastructure safety and monitoring solutions available through platforms such as construction technology systems, where inspection data supports long-term asset reliability and operational continuity.

Magnetic Tomography Technology for Pipeline Inspection

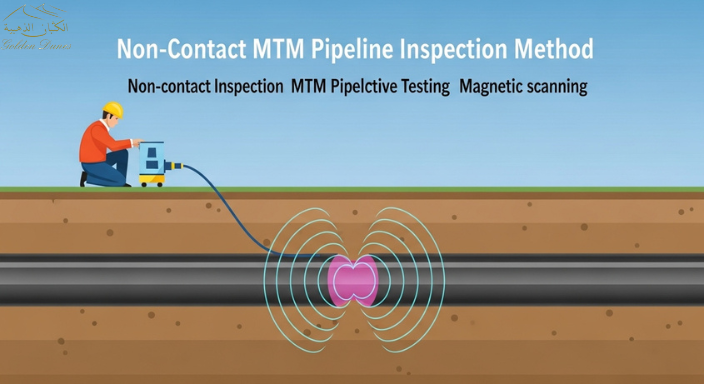

Magnetic tomography technology represents an advanced inspection approach that analyzes variations in the magnetic field surrounding a pipeline to evaluate its technical condition. In the context of what is MTM pipeline inspection, this technology enables engineers to inspect pipelines externally and collect reliable information without physical contact with the pipe surface.

Unlike conventional inspection methods that depend on internal tools or direct access to the pipeline, magnetic tomography operates as a non-contact inspection system. It focuses on identifying changes in the magnetic field caused by defects in the metal, stress concentration, corrosion, or metal loss along the pipeline length.

Core Principles of Magnetic Tomography Technology

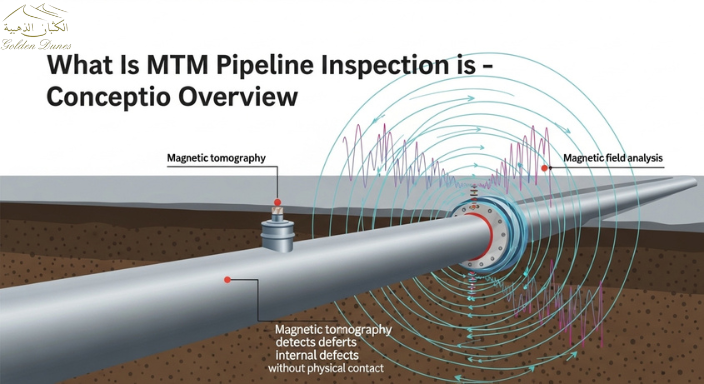

The core principle of magnetic tomography is based on monitoring magnetic field behavior around ferromagnetic materials such as metal pipelines. When a pipeline experiences stress, crack development, or corrosion, the magnetic field distribution changes accordingly. These changes can be detected and analyzed to determine defect location, affected area, and severity level.

By applying this inspection method, engineers are able to detect abnormal magnetic signals that indicate variations in pipeline condition. The collected data supports accurate defect detection without interrupting pipeline operation, making the technology suitable for industrial environments where continuous service is required.

How MTM Technology Detects Pipeline Anomalies

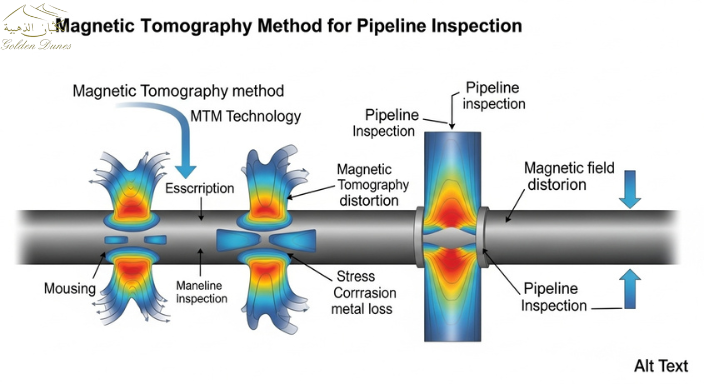

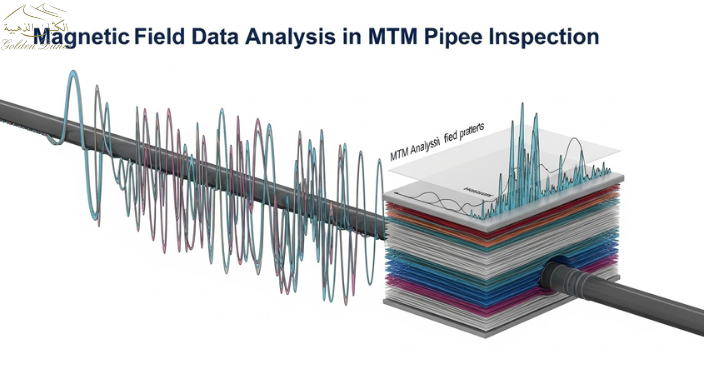

MTM inspection technology relies on advanced detection systems to scan the pipeline externally and record magnetic field data over time. This process allows inspectors to identify areas affected by corrosion, metal loss, or stress-related defects that may compromise pipeline reliability.

During inspection, magnetic signals are analyzed to assess changes in the field pattern surrounding the pipe. These changes provide critical information about the internal condition of the metal structure, enabling defect detection at an early stage and supporting informed inspection decisions within non-destructive testing programs.

Technology Readiness Level (TRL) of MTM Inspection

Evaluating the Technology Readiness Level is an essential step when assessing what is MTM pipeline inspection as an inspection method within industrial environments. TRL provides a structured framework to determine how mature, reliable, and applicable a technology is for real-world pipeline inspection work.

In magnetic tomography inspection, readiness level assessment focuses on the stability of the detection system, the accuracy of collected data, and the reliability of defect detection under different operating conditions. This evaluation helps decision-makers understand whether the technology can be used safely and effectively within active pipeline networks.

Evolution of MTM Technology Across TRL Stages

MTM inspection technology has progressed through multiple readiness levels, moving from controlled engineering tests to full-scale industrial application. Early stages focused on validating the magnetic tomography method and its ability to detect defects in the metal under laboratory conditions.

As the technology advanced, field inspections demonstrated its capability to operate across extended pipeline length and varied environments. These developments confirmed the method’s reliability for detecting corrosion, stress concentration, and metal loss without direct contact with the pipe.

Reliability of MTM in Industrial Pipeline Environments

Reliability is a key factor in determining the practical value of MTM inspection technology. In industrial pipeline inspection, reliability depends on consistent magnetic field detection, accurate data interpretation, and the system’s ability to operate over time without performance degradation.

By maintaining stable detection parameters and delivering repeatable inspection results, MTM inspection supports informed decisions related to pipeline condition, risk management, and long-term integrity planning within non-destructive testing programs used across the industry.

Pipeline Survey and Integrity Assessment

Pipeline survey plays a central role in understanding the overall technical condition of pipeline systems and identifying potential danger areas before failure occurs. Within the framework of what is MTM pipeline inspection, pipeline inspection is conducted through external scanning that supports integrity assessment without direct contact with the pipe.

This inspection method enables engineers to inspect large pipeline areas efficiently while collecting structured data related to corrosion, crack development, stress concentration, and metal loss. The resulting information supports accurate condition evaluation and helps reduce inspection time compared to traditional contact-based methods.

Role of Pipeline Surveys in Integrity Management

Pipeline surveys are essential for maintaining long-term pipeline integrity and ensuring operational safety across industrial facilities. By using magnetic field detection systems, inspectors are able to detect changes that indicate defects in the metal structure, even when pipelines are buried or inaccessible.

Survey results provide critical input for integrity management programs, allowing operators to prioritize inspection work, allocate resources efficiently, and reduce operational risk associated with undetected corrosion or structural stress within the pipeline system.

Data Interpretation and Risk Identification

Accurate data interpretation is fundamental to effective pipeline inspection. Magnetic tomography inspection systems generate detailed information related to field variation, defect location, and severity level, which must be analyzed carefully to determine actual pipeline condition.

By evaluating magnetic field changes and correlating them with known defect patterns, engineers can identify risk areas, assess the degree of metal loss, and support informed inspection decisions that enhance reliability and reduce potential danger during pipeline operation.

Government Support and Regulatory Frameworks

Government support and regulatory frameworks play a critical role in shaping how pipeline inspection technologies are applied across the industry. In the context of what is MTM pipeline inspection, regulatory requirements influence how inspection methods are selected, validated, and integrated into broader safety and compliance systems.

Inspection technology based on magnetic tomography must align with established inspection standards and non-destructive testing guidelines to ensure reliable defect detection, data accuracy, and responsible inspection practices that reduce operational danger.

Compliance with Pipeline Inspection Standards

Compliance with pipeline inspection standards ensures that inspection methods operate within defined technical and safety parameters. Magnetic tomography inspection systems are evaluated based on their ability to detect defects in the metal, assess corrosion and stress concentration, and provide consistent inspection results over time.

By adhering to recognized inspection frameworks, organizations strengthen inspection reliability and support responsible pipeline condition monitoring without introducing unnecessary operational risk.

Integration with Infrastructure Safety Regulations

Integration with infrastructure safety regulations requires inspection systems to operate as part of a broader risk management and safety framework. Magnetic field detection data generated during inspection contributes to informed decision-making related to pipeline condition, maintenance planning, and resource allocation.

When inspection technology is aligned with regulatory expectations, it supports safer industrial operations and enhances the overall reliability of pipeline systems operating in high-risk environments.

Key Advantages of MTM Pipeline Inspection

Understanding the key advantages of MTM pipeline inspection is essential when evaluating what is MTM pipeline inspection as an inspection method within industrial systems. This technology provides measurable advantages related to defect detection, inspection reliability, and operational continuity without direct contact with the pipe.

By relying on magnetic field analysis rather than physical access, MTM inspection reduces inspection preparation time and minimizes operational disruption, making it suitable for complex pipeline environments where safety and efficiency are critical.

Early Detection of Hidden Pipeline Defects

One of the primary advantages of MTM inspection technology is its ability to detect hidden defects in the metal structure at an early stage. Changes in the magnetic field allow inspectors to identify corrosion, crack formation, stress concentration, and metal loss before these issues escalate into operational danger.

Early detection supports informed decision-making, reduces repair costs, and enhances the overall reliability of pipeline inspection programs across industrial facilities.

Non-Intrusive Inspection Without Operational Disruption

MTM inspection operates as a non-contact and non-destructive testing method, eliminating the need for internal access or pipeline shutdown. This inspection approach allows continuous operation while collecting accurate inspection data related to pipeline condition.

By avoiding physical contact and invasive inspection methods, MTM inspection minimizes operational risk, preserves pipeline integrity, and supports efficient inspection workflows across extended pipeline lengths.

Core Features of Magnetic Tomography Inspection

The core features of magnetic tomography inspection define how this technology supports reliable pipeline inspection within industrial systems. When examining what is MTM pipeline inspection, these features explain how inspection can be performed externally while maintaining accuracy, safety, and operational continuity.

Magnetic tomography inspection systems are designed to operate without direct contact, using magnetic field detection to identify defects in the metal structure and assess pipeline condition over extended areas.

Remote Signal-Based Inspection Capabilities

A key feature of magnetic tomography inspection is its reliance on remote signal detection rather than physical interaction with the pipe. Magnetometer-based systems measure variations in the magnetic field to detect corrosion, crack development, stress concentration, and metal loss within the pipeline.

This signal-based inspection method enables inspectors to scan pipelines efficiently, collect structured data, and evaluate technical condition without interrupting normal operation or introducing additional inspection risk.

Adaptability to Complex and Buried Pipelines

Magnetic tomography inspection technology is adaptable to complex pipeline layouts, including buried pipelines and installations located in difficult-to-access environments. Its non-contact nature allows inspection work to proceed without excavation or direct exposure to the pipe surface.

By supporting inspection across different pipeline conditions and environments, this feature enhances inspection reliability and expands the practical application of magnetic tomography within industrial inspection programs.

Practical Applications of MTM Pipeline Inspection

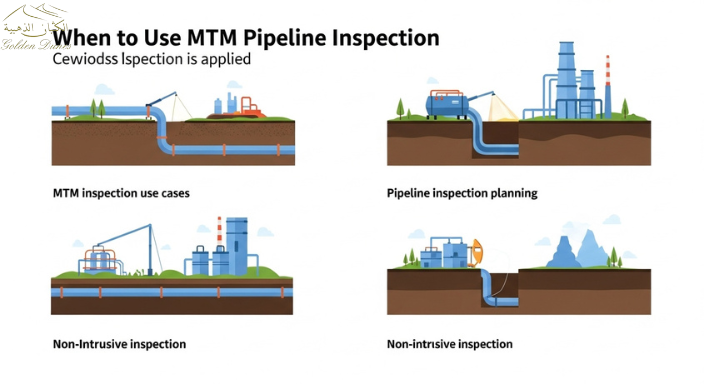

Practical applications illustrate how MTM inspection technology is used across different industrial environments to support safe and reliable pipeline inspection. Understanding what is MTM pipeline inspection includes recognizing how this inspection method operates under real work conditions without direct contact or service interruption.

By relying on magnetic field detection and structured data analysis, MTM inspection supports inspection activities across facilities where access limitations, operational continuity, and safety concerns require non-intrusive inspection solutions.

Use of MTM in Oil and Gas Pipeline Networks

In oil and gas pipeline networks, MTM inspection is applied to detect defects in the metal structure that may result from corrosion, stress concentration, or metal loss. External inspection allows pipelines to be inspected while remaining in operation, reducing inspection time and operational risk.

This inspection method supports condition assessment across long pipeline lengths, enabling inspectors to identify critical areas that require further inspection or maintenance planning.

Applications in Industrial and Critical Infrastructure

MTM inspection technology is also applied within industrial and critical infrastructure environments where pipelines operate under complex conditions. Facilities that require continuous operation benefit from inspection systems capable of detecting defects without physical contact or invasive preparation.

By supporting reliable defect detection and condition monitoring, MTM inspection contributes to safer infrastructure operation and informed decision-making across industrial inspection programs.

Engineering Challenges and Practical Considerations

Despite the advantages of MTM inspection technology, understanding what is MTM pipeline inspection also requires evaluating engineering challenges and practical considerations associated with its application. These considerations influence how inspection data is interpreted and how inspection results are integrated into broader pipeline inspection programs.

One practical challenge relates to magnetic field behavior in complex environments where external factors may affect signal clarity. Variations in metal condition, stress concentration, and surrounding infrastructure can influence detection accuracy and require careful inspection planning and preparation.

Another consideration involves data interpretation and reliability. Magnetic tomography inspection systems generate large volumes of inspection data that must be analyzed accurately to distinguish between true defects and normal changes in magnetic field patterns. This process demands technical expertise and structured inspection procedures to ensure reliable results.

MTM inspection is most effective when integrated with other non-destructive testing methods as part of a comprehensive inspection strategy. Combining inspection data from multiple sources enhances overall pipeline condition assessment and supports informed risk management decisions across industrial inspection environments.

🟫 Frequently Asked Questions About MTM Pipeline Inspection

Conclusion and Engineering Call to Action

In high-risk pipeline environments where operational continuity, safety, and asset longevity are critical, understanding what is MTM pipeline inspection requires more than reviewing inspection tools alone. Effective pipeline integrity management depends on inspection logic, data reliability, and the ability to detect hidden defects without interrupting pipeline operation or increasing operational risk.

Magnetic tomography inspection provides a non-contact, non-destructive testing approach that enables early detection of corrosion, stress concentration, crack development, and metal loss by analyzing magnetic field behavior around the pipeline. This capability allows engineering teams to assess technical condition accurately while maintaining continuous operation across complex and buried pipeline systems.

When applied within a structured inspection framework and aligned with recognized inspection standards, MTM inspection enhances pipeline reliability, supports informed engineering decisions, and strengthens long-term infrastructure management strategies. Its adaptability to diverse pipeline environments makes it a valuable component within integrated pipeline inspection and integrity assessment programs.

📩 Next Steps for Engineering and Asset Integrity Teams

For engineering decision-makers and asset integrity teams seeking reliable inspection data to support risk assessment, maintenance planning, and long-term pipeline performance, integrating MTM pipeline inspection within broader inspection strategies offers a clear technical advantage. Proper evaluation of inspection data enables earlier intervention, optimized resource allocation, and reduced exposure to failure-related risks.

To explore how magnetic tomography inspection can be applied within real-world pipeline environments—covering inspection planning, data interpretation, and integration with existing integrity programs—specialized technical guidance is available through Golden Dunes engineering resources.

🔍 Explore MTM Pipeline Inspection Framework

📞 Call or WhatsApp: +966 580 404 030

By adopting magnetic tomography inspection as part of a structured pipeline integrity framework, organizations enhance inspection reliability, reduce operational uncertainty, and support responsible infrastructure management across critical pipeline networks.